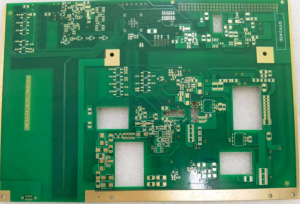

How to do edge plating on PCB board

At present, there are two kinds of PCB board edge design metallization andnon-metallization. Fornon-metallization, manufacturers in the assiduity have progressed, but the metallization technology is still immature. Currently, further guests’ product requirements are turning to PCB metal edging. Thus, the quality of PCB essence edging has come the focus of guests’and manufacturers’ attention because its quality directly affects the use of products.

What are the operations of edge plating in PCB?

Edge plating circuit boards are common in numerous diligence, and edge plating is a common practice. You ’ll find PCB edge castellation (or edge plating PCBs) applied in numerous cases, including

· Perfecting current- carrying capabilities

· Edge connections and protection

· Edge soldering to ameliorate fabrication

· More support for connections similar as boards that slide into essence coverings

What's the process of PCB edge plating?

As you know, there are a great deal of challenges for a multilayer PCB manufacturer substantially in how to prepare the plated edges and the life span adhesion of the plated material, what’s more, it needs the perfection handling in PCB manufacturing that's used for edge PCB soldering. We can make sure that the PCB edge castellation completely prepares edges shells, which applies the plated bobby for prompt adhesion and processes the circuit board to make sure the long- term adhesion between each subcaste.

Dispensable to say, we can control the implicit hazard for plated through hole and edge plating with a controlled process during published circuit board manufacturing for edge soldering. So the most important concern is the creation of churrs, which affect in discontinuities in plated through hole walls and limits the life of adhesion of the edge plating.

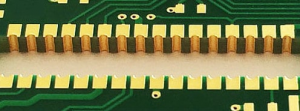

The external silhouettes, to be metalized, must be mulled before through- hole plating process, as the metallization of the edges take place during this fabrication step. After the deposit of bobby, the intended face finish is eventually applied to the edges.

Fabrication Issues

1. Bobby Peeling-Plating over a large substrate face can lead to the plated bobby shelling due to a lack of adhesion strength. We address this by first planing the face through a combination of chemical and other personal means. Next, we employ direct metallization, which has a advanced bobby bond strength, to prepare the face for plating.

2. Churrs- Frequently edge plating, especially on castellation holes, can affect in churrs from the final machining process. We apply a modified, personal process inflow that results in the churrs being polished down to the edge of the point.

Fab Note

1. The antenna position of the gold pad is too large, affecting client soldering or signal transmission.

2. The inner edge pad is connected to the cables on the board, performing in a short circuit.

3. The stamp hole is designed at the edging groove and must be handled in the 2nd drilling process.

4. Through the process- related manufacture of the individual PCBs as a panel, a nonstop metallization of the external edges isn't possible. No metallization can be applied where the small panel islands are located.

5. One request, the slide plating metallization can be covered with solder mask.

When copping edge plating boards, you must confirm with your PCB supplier the possibility of manufacturing PCBs with plating process, and extent to which the liar can edge plate the PCB. Your Gerber lines or fab delineation should indicate in a mechanical subcaste where they need slide plating, and the face finish they need on it. Utmost manufacturers prefer a picky ENIG as the only face finish suitable for round castellation.

YMS ElectronicsCo.,Ltd. is a professional manufacturer of high- perfection multilayer circuit boards, module absorption gold circuit boards, automotive circuit boards, driving reporters, COB power inventories, computer motherboards, medical circuit boards, module cling boards, eyeless hole impedance board, thermoelectric separation bobby substrate, etc. RayMing provides top- notch quality assurance and immediate delivery, a high-tech enterprise with deals as awhole.However, please feel free to communicate us!

If there's a demand for side- carpeted gold boards.

Address:

HuiZHou Plant: ECheng Industrial Park,11 Xinke Avenue,Tongqiao Town,Zhongkai High-Tech Zone,Huizhou City Guangdong Province China

MB: 0086-15986993949

TEL: 0086-(0)752-2050781

FAX: 0086-(0)752-2050783

E-mail:Joyce@ymspcb.com

评论

发表评论