How to make aluminum PCB boards

Aluminum PCB Manufacturing Process

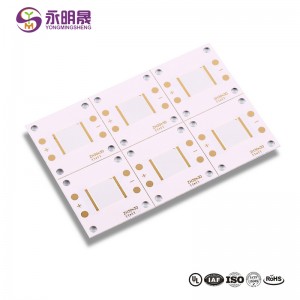

Aluminum PCB Manufacturing ProcessThe manufacturing process of aluminum PCB with OSP surface finish Cutting → Drilling → Circuit → Acid/ alkaline drawing → Solder Mask → Silkscreen → V- cut → PCB Test → OSP → FQC → FQA → Quilting → Delivery.

The manufacturing process of aluminum PCB with HASL face finish Cutting → Drilling → Circuit → Acid/ alkaline drawing → Solder Mask → Silkscreen → HASL → V- cut → PCB Test → FQC → FQA → Quilting → Delivery.

YMSPCB can give the aluminum core PCB with the same face finish process as FR-4 PCB Absorption Gold/ thin/ tableware, OSP, etc.

In the process of manufacturing an aluminum PCB, a thin subcaste of dielectric is added between the circuit subcaste and the base subcaste. This subcaste of dielectric is both electrically separating, as well as thermally conductive. After adding the dielectric subcaste, the circuit subcaste or the bobby antipode is etched

https://www.ymspcb.com/news/how-to-make-aluminum-pcb-boards-yms

Notice

1. Put boards in the pen-shelf or separate them with paper or plastic wastes to avoid scrapes during transportation of the whole product.

2. Using a cutter to scratch an insulated subcaste in any process isn't allowed during the whole product.

3. For abandoned boards, the base material can not be drilled but is only marked with “ X” by canvas-pen.

4. Total pattern examination is a must because there's no way to break the pattern problem after etching.

5. Conduct 100 IQC checks for all out-sourcing boards according to our company’s norms.

6. Gather all imperfect boards together ( similar as dim color & scrapes of the AI face) to bere-processed.

7. Any problem during product must be informed to affiliated specialized staff in time to be answered.

8. All processes must be rigorously operated ensuing conditions.

To read more, please click here:

YONGMINGSHENG TECHNOLOGY CO., LTD.

评论

发表评论