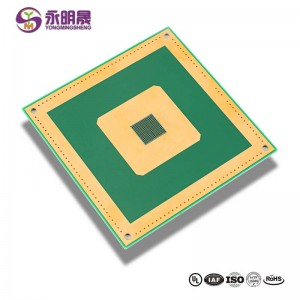

Heavy copper printed circuit boards

Generally, the bobby consistence of a standard PCB is 1oz to 3oz. Thick- copper PCBs or heavy- copper PCBs are the types of PCBs that the finished bull weight is further than 4oz (140μm). The thick bull allows large PCB-cross-sections for high current loads and encourages heat dissipation. The most common designs are multilayer or double-sided. With this PCB technology it's also possible to combine fine layout structures on the external layers and thick bull layers in the inner layers.

https://www.ymspcb.com/heavy-copper-pcb-thick-copper-board-power-pcb

The thick- bull PCB belongs to a special type of PCB. its conductive paraphernalia, substrate paraphernalia, product process, operation fields are different from the conventional PCBs. The plating of thick bull circuits allows PCB manufacturers to increase the bull weight by via sidewalls and plated holes, which can reduce the caste numbers and vestiges. Thick- bull plating integrates high-current and control circuits, making high- density with simple board structures can be achieved.

The construction of heavy- bull circuits gives the PCBs the following advantages

1. Increase current capacity greatly

2. Advanced abidance to thermal strains

3. Better heat dissipation

4. Increase the mechanical strength at connectors and PTH holes

5. Reduce the product size

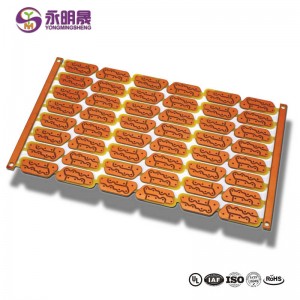

The operations of thick- bull PCBs

Along with the adding of high- power products, the demand for thick- bull PCBs is greatly increased. Moment’s PCB manufacturers pay farther attention to using a thick bull board to break the thermal effectiveness of high- power electronics.

The thick- bull PCBs are mainly large current substrate, and large current PCBs are mainly used in power module and automotive electronic corridor. Traditional automotive, power force, and power electronics operations use the original forms of transmission like string distribution and substance distance. Now the thick- bull boards replace the transmission form, which not only can meliorate productivity and reduce the time cost of wiring, but also increase the responsibility of final products. At the same time, the massive current boards can meliorate the design freedom of wiring, thus realizing the miniaturization of the whole product.

Thick-bobby circuit PCB play an irreplaceable part in the operations with high- power, high current, and high cooling demand. The manufacturing process and paraphernalia of heavy-bobby PCBS have important advanced conditions than standard PCBs. With advanced outfit and professional engineers, YMS provides thick- bull PCBs with high- quality for guests from home and abroad.

To learn more, please click here:

YONGMINGSHENG TECHNOLOGY CO., LTD.

评论

发表评论